Yamaha Tracer MT09TRA - Owner's Manual > Rear brake pads

Yamaha Tracer MT09TRA - Owner's Manual > Rear brake pads

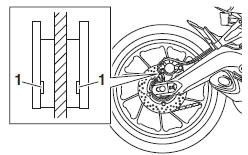

- Brake pad wear indicator groove

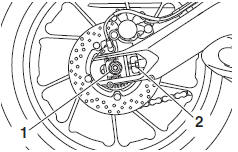

Each rear brake pad is provided with wear indicator grooves, which allow you to check the brake pad wear without having to disassemble the brake.

To check the brake pad wear, check the wear indicator grooves. If a brake pad has worn to the point that a wear indicator groove almost appears, have a Yamaha dealer replace the brake pads as a set.

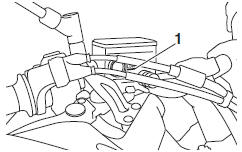

Checking the brake fluid level

Before riding, check that the brake fluid is above the minimum level mark.

Check the brake fluid level with the top of the reservoir level. Replenish the brake fluid if necessary.

Front brake

- Minimum level mark

Rear brake

- Minimum level mark

Specified brake fluid: DOT 4

WARNING

Improper maintenance can result in loss of braking ability. Observe these precautions:

- Insufficient brake fluid may allow air to enter the brake system, reducing braking performance.

- Clean the filler cap before removing.

Use only DOT 4 brake fluid from a sealed container.

- Use only the specified brake fluid; otherwise, the rubber seals may deteriorate, causing leakage.

- Refill with the same type of brake fluid. Adding a brake fluid other than DOT 4 may result in a harmful chemical reaction.

- Be careful that water or dust does not enter the brake fluid reservoir when refilling. Water will significantly lower the boiling point of the fluid and may result in vapor lock, and dirt may clog the ABS hydraulic unit valves.

NOTICE

Brake fluid may damage painted surfaces or plastic parts. Always clean up spilled fluid immediately.

As the brake pads wear, it is normal for the brake fluid level to gradually go down. A low brake fluid level may indicate worn brake pads and/or brake system leakage; therefore, be sure to check the brake pads for wear and the brake system for leakage. If the brake fluid level goes down suddenly, have a Yamaha dealer check the cause before further riding.

Changing the brake fluid

Have a Yamaha dealer change the brake fluid at the intervals specified in the periodic maintenance and lubrication chart. In addition, have the oil seals of the master cylinders and calipers as well as the brake hoses replaced at the intervals listed below or whenever they are damaged or leaking.

- Oil seals: Replace every two years.

- Brake hoses: Replace every four years.

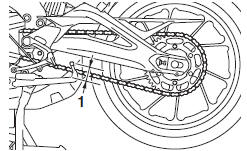

Drive chain slack

The drive chain slack should be checked before each ride and adjusted if necessary.

To check the drive chain slack

1. Place the motorcycle on the centerstand.

2. Shift the transmission into the neutral position.

3. Measure the drive chain slack as shown.

- Drive chain slack

Drive chain slack: 5.0-15.0 mm (0.20-0.59 in)

4. If the drive chain slack is incorrect, adjust it as follows.

To adjust the drive chain slack

Consult a Yamaha dealer before adjusting the drive chain slack.

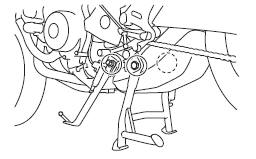

1. Take the motorcycle off the centerstand, and then put the sidestand down.

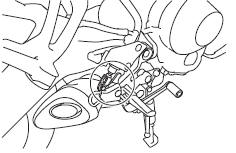

2. Loosen the axle nut and the locknut on each side of the swingarm.

- Axle nut

- Locknut

3. Place the motorcycle on the centerstand.

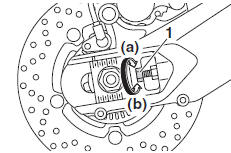

4. To tighten the drive chain, turn the drive chain slack adjusting bolt on each side of the swingarm in direction (a). To loosen the drive chain, turn the adjusting bolt on each side of the swingarm in direction (b), and then push the rear wheel forward.

NOTICE: Improper drive chain slack will overload the engine as well as other vital parts of the motorcycle and can lead to chain slippage or breakage. If the drive chain slack is more than 25.0 mm (0.98 in), the chain can damage the frame, swingarm, and other parts. To prevent this from occurring, keep the drive chain slack within the specified limits.

- Drive chain slack adjusting bolt

TIP

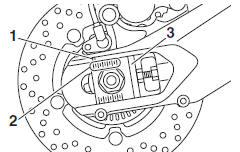

Using the alignment marks on the drive chain pullers and the notch on each side of the swingarm, make sure that both drive chain pullers are in the same position for proper wheel alignment.

- Notch

- Alignment mark

- Drive chain puller

5. Take the motorcycle off the centerstand, and then put the sidestand down.

6. Tighten the axle nut, then the locknuts to their specified torques.

Tightening torques:

Axle nut:

150 Nm (15 m*kgf, 108 ft*lbf)

Locknut:

16 Nm (1.6 m*kgf, 12 ft*lbf)

7. Make sure that the drive chain pullers are in the same position, the drive chain slack is correct, and the drive chain moves smoothly.

Cleaning and lubricating the drive chain

The drive chain must be cleaned and lubricated at the intervals specified in the periodic maintenance and lubrication chart, otherwise it will quickly wear out, especially when riding in dusty or wet areas. Service the drive chain as follows.

NOTICE

The drive chain must be lubricated after washing the motorcycle, riding in the rain or riding in wet areas.

1. Clean the drive chain with kerosene and a small soft brush.

NOTICE: To prevent damaging the O-rings, do not clean the drive chain with steam cleaners, high-pressure washers or inappropriate solvents

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain lubricant.

NOTICE: Do not use engine oil or any other lubricants for the drive chain, as they may contain substances that could damage the O-rings.

Checking and lubricating the cables

The operation of all control cables and the condition of the cables should be checked before each ride, and the cables and cable ends should be lubricated if necessary. If a cable is damaged or does not move smoothly, have a Yamaha dealer check or replace it.

WARNING! Damage to the outer housing of cables may result in internal rusting and cause interference with cable movement. Replace damaged cables as soon as possible to prevent unsafe conditions

Recommended lubricant:

Yamaha cable lubricant or other suitable cable lubricant

Checking and lubricating the throttle grip and cable

The operation of the throttle grip should be checked before each ride. In addition, the cable should be lubricated by a Yamaha dealer at the intervals specified in the periodic maintenance chart.

The throttle cable is equipped with a rubber cover. Make sure that the cover is securely installed. Even though the cover is installed correctly, it does not completely protect the cable from water entry. Therefore, use care not to pour water directly onto the cover or cable when washing the vehicle. If the cable or cover becomes dirty, wipe clean with a moist cloth.

Checking and lubricating the brake and shift pedals

The operation of the brake and shift pedals should be checked before each ride, and the pedal pivots should be lubricated if necessary.

Brake pedal

Shift pedal

Recommended lubricant:

Lithium-soap-based grease

Checking and lubricating the brake and clutch levers

The operation of the brake and clutch levers should be checked before each ride, and the lever pivots should be lubricated if necessary.

Brake lever

Clutch lever

Recommended lubricants:

Brake lever:

Silicone grease

Clutch lever:

Lithium-soap-based grease

Checking and lubricating the centerstand and sidestand

The operation of the centerstand and sidestand should be checked before each ride, and the pivots and metal-tometal contact surfaces should be lubricated if necessary.

WARNING

If the centerstand or sidestand does not move up and down smoothly, have a Yamaha dealer check or repair it. Otherwise, the centerstand or sidestand could contact the ground and distract the operator, resulting in a possible loss of control.

Recommended lubricant: Lithium-soap-based grease

See also:

Yamaha Tracer MT09TRA - Owner's Manual > Air filter element

Yamaha Tracer MT09TRA - Owner's Manual > Air filter element

The air filter element must be replaced at the intervals specified in the periodic maintenance and lubrication chart. Have a Yamaha dealer replace the air filter element. Checking the engine idling speed

Yamaha Tracer MT09TRA - Owner's Manual > Lubricating the swingarm pivots

Yamaha Tracer MT09TRA - Owner's Manual > Lubricating the swingarm pivots

The swingarm pivots must be lubricated by a Yamaha dealer at the intervals specified in the periodic maintenance and lubrication chart.

BMW G310GS

BMW G310GS Honda CBR125RW

Honda CBR125RW Husqvarna 401 Vitpilen

Husqvarna 401 Vitpilen KTM 890 Duke R

KTM 890 Duke R Mash Dirt Track 650

Mash Dirt Track 650 Peugeot Kisbee

Peugeot Kisbee Yamaha Tracer MT-09

Yamaha Tracer MT-09 Honda CBR125RW

Honda CBR125RW Peugeot Kisbee

Peugeot Kisbee Yamaha Tracer MT-09

Yamaha Tracer MT-09