Mash Dirt Track 650 - Owner's Manual > Engine Management System

Mash Dirt Track 650 - Owner's Manual > Engine Management System

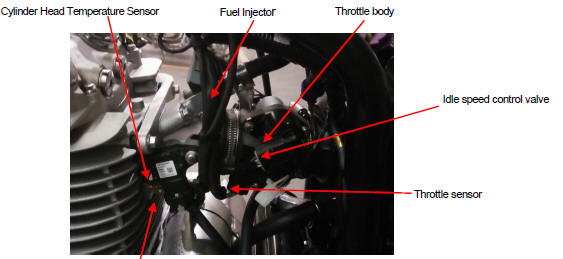

The Engine Management System (EMS) is comprised of the following components: Electronic control unit (ECU), throttle body, Idle speed control valve, fuel pump, fuel injector, ignition coil, O2 sensor, throttle position sensor, T-MAP sensor, cylinder head temperature sensor, etc.

The EMS uses sensors to collect parameters such as air flow, temperature of inlet air, cylinder head temperature, atmospheric pressure and the operational state of engine (rpm, load, acceleration and deceleration). All parameters are transferred to the ECU via electronic signal. The ECU outputs control signals after the input signals have been processed. Based on the air flow and engine speed, the fuel injector and ignition coil are controlled by ECU to get the optimal combustible mixture of fuel and air and Ignition timing which meet all engine operating conditions.

Through the engine and actuator components on the vehicle (ignition coil, fuel injector, idle speed control valve and so on), the fuel and spark are precisely controlled and corrected with closed loop.

System composition:

- Sensors:

- Intake air pressure sensor (load information) intake air temperature and pressure sensors

- Throttle position sensor (load information, load range information, acceleration / deceleration information)

- Engine speed sensor (speed information, crankshaft position)

- Intake air temperature sensor (air density information)

- Oxygen sensor (information of the excess air coefficient is more than 1 or less than 1)

- Actuators:

- Fuel pump relay

- Fuel pump

- Fuel injector (fuel supply)

- Ignition coil

- High tension cord

- Spark plug (ignition)

- Throttle, Idle speed control valve (air intake)

- Electronic control unit

- ECU

Major Components of EFI System

Intake air pressure sensor

Electronic Control Unit (ECU)

Oxygen sensor

Circuit schematic drawing

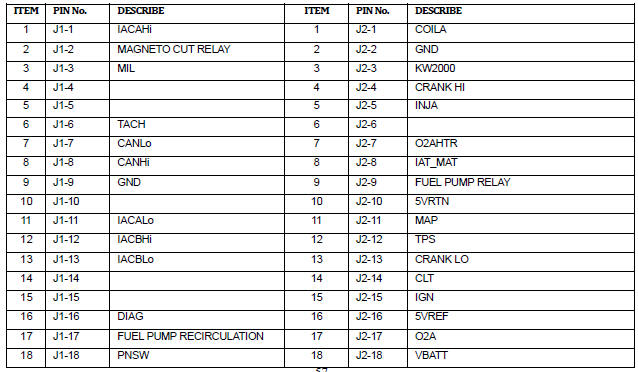

Definition ECU pins

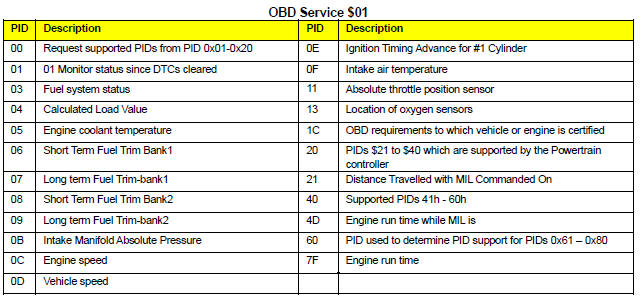

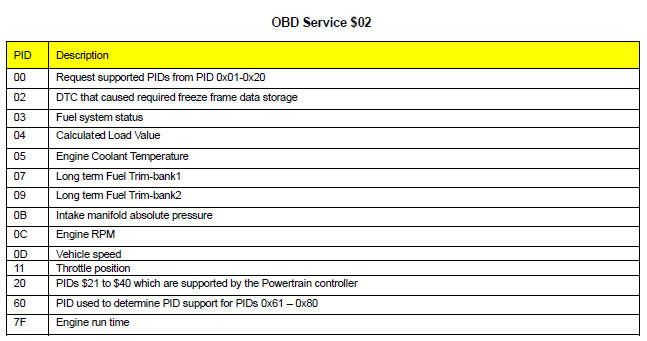

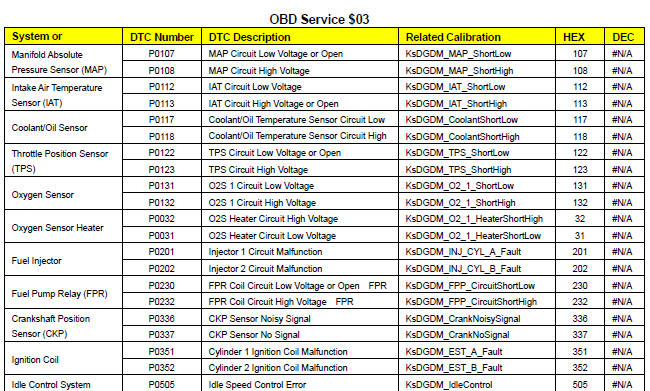

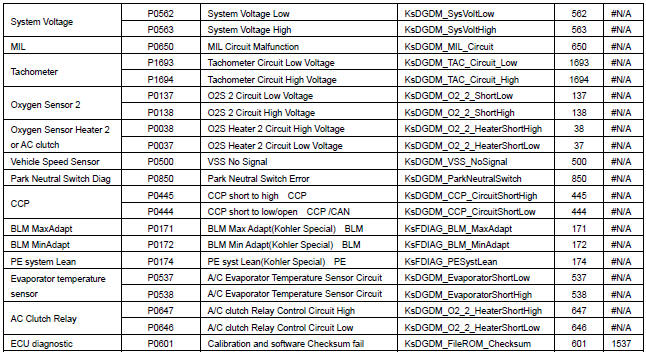

EMS failure diagnosis code list

Engine Management Troubleshooting

EFI systems are complex. As such, there are many possible causes when a running issue is encountered. At times it can be confusing if an issue is caused by a mechanical problem or the EFI components.

Always contact your genuine dealer if you are having trouble with your vehicle's Engine Management System.

EFI System Maintenance Procedures

- Do not disassemble components arbitrarily. It may damage the components.

- Turn the ignition off prior to connecting or disconnecting any connector including diagnostic controller.

- Make sure the temperature of the ECU is below 175º F

- The fuel pressure is very high (about 36 psi), so please do not disassemble the fuel line arbitrarily. If the fuel line needs to be removed, please release the pressure first, and make service is completed in a ventilated area by genuine technicians.

- When disassembling the fuel pump, make sure the power is off or it may cause fire.

- The fuel pump cannot be contaminated with air or water, as it will shorten the useful life. The positive and negative poles of the fuel pump cannot be reversed.

- The ignition system check should only be completed when it is necessary. When checking the spark plug out of the engine, make sure the throttle is closed. Excess unburned fuel coming into the catalyst may damage the catalyst.

- The idle speed is adjusted by the ECU. The idle screw is not to be adjusted.

- The Positive and Negative poles of the battery cannot be reversed. It may damage the EFI components.

- Do not remove the battery when the engine is running.

- Do not attempt to measure electrical signals by piercing the wire harness.

Electrical system diagram

See also:

Mash Dirt Track 650 - Owner's Manual > Cleaning the Motorcycle

Mash Dirt Track 650 - Owner's Manual > Cleaning the Motorcycle

To keep the body and paint in good condition, wash your motorcycle often. The best way to clean your motorcycle is to use warm water combined with detergent to remove the dirt. Attention: Do not use high-pressure water to wash the motorcycle. Do not point water spray directly at electrical parts, plugs, cables, bearings, ECU, etc. High pressure water sources will cause water to enter into secure parts leading to functional failure and premature aging. Use ordinary detergent brands to clean your motorcycle. For the most difficult areas use a brush to clean. Plug the muffler before cleaning, to prevent water from getting inside the muffler. After washing, dry off the motorcycle. Ride for a distance until the engine has reached a working temperature; meanwhile apply the brake to evaporate the water left inside. Since the motorcycle cools down, please grease all the sliding parts, bearings and oil plug with lubricating oil. Protect your electric system to avoid any foreign materials entering.

BMW G310GS

BMW G310GS Honda CBR125RW

Honda CBR125RW Husqvarna 401 Vitpilen

Husqvarna 401 Vitpilen KTM 890 Duke R

KTM 890 Duke R Mash Dirt Track 650

Mash Dirt Track 650 Peugeot Kisbee

Peugeot Kisbee Yamaha Tracer MT-09

Yamaha Tracer MT-09 Honda CBR125RW

Honda CBR125RW Peugeot Kisbee

Peugeot Kisbee Yamaha Tracer MT-09

Yamaha Tracer MT-09