Mash Dirt Track 650 - Owner's Manual > Spark Plug

Mash Dirt Track 650 - Owner's Manual > Spark Plug

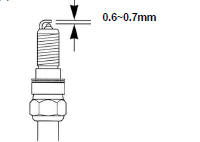

Remove the spark plug cap, then remove the spark plug with a socket wrench. Visually check whether there is damage to the spark plug insulator or electrodes. If damage has occurred, replace the spark plug. Check the spark plug electrode gap with a plug gauge. Spark plug electrode gap 0.6 -0.7mm. Carefully adjust the electrode gap.

Carefully remove any accumulated carbon and contaminants with a spark plug cleaner or soft wire brush. Ensure the spark plug washer is in good condition.

Insert the spark plug, hand-tighten the spark plug first, and then tighten it with a socket wrench. Replace the spark plug cap.

Upon completion of inspection, mount the cam phase sensor, eyehole cover and upper eyehole cover in turn.

Engine Oil

Use SJ 15W40 in the summer or 10W30 in the winter in order to ensure maximum engine performance. Using a high-quality engine oil designed and tested for use in your vehicle will also extend the life of the engine. Using lighter weight engine oil in cooler climates is acceptable.

Caution

Insufficient quantity or poor quality engine oil will lead to premature engine wear, damage or engine failure.

Engine oil plays a very important role in the normal operation of the engine. Your motorcycle relies upon the oil to aid in cooling. As such, it is extremely important to use quality oil and it is necessary to check the motorcycle engine oil level regularly and replace the oil at 800km, at 2000Km, then every 4000Km thereafter.

Engine oil replacement

Drain the oil while the engine is warm. A warm engine will ensure quick and complete discharge of the engine oil inside the crankcase.

To replace the oil: Unscrew the oil drain plug and completely discharge the waste engine oil.

Clean the oil drain plug, engine oil strainer / filter, etc.

Re-insert the oil drain plug. Unscrew the oil fill plug and slowly refill engine with 1.8L oil per specification into the crankcase. Re- insert the oil fill plug.

Oil drain plug

Caution

When the engine is at an operating temperature, the engine oil may be very hot, so be careful not to burn yourself.

Place the motorcycle on a flat surface. Remove the drain plug, then drain engine oil. Once all oil has been removed, clean the gasket and drain plug thoroughly, tighten plug to 28N.m.

Oil dipstick must be reinstalled properly, or the oil dipstick will provide false readings level can cause damage to the engine.

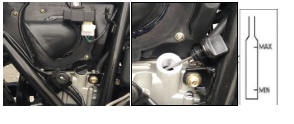

Oil level check

Run the engine for 2-3 minutes. Check whether or not the engine oil level is in the middle of the range on the engine oil dipstick. Add oil if necessary.

Cleaning the oil sump

- Drain the engine oil thoroughly.

- Disassemble each part.

- Clean each part.

- Refill with the proper engine oil.

- Clean the sump.

- Work should be performed by an Authorized Genuine Motorcycle dealer.

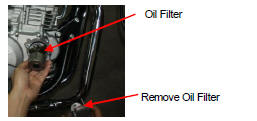

Cleaning the Oil Filter

- Remove the engine oil filter cover and remove the engine oil filter element.

- Clean the filter cover and filter element with cleaning agent, and then re-install the clean engine oil filter.

- Replace oil filter as required.

- Inspect for damage of the engine oil filter cover and its 0-ring seal; replace 0-ring as required.

- Re-install the engine oil filter cover and tighten bolts to the specified torque.

Notice

Before the crankcase is refilled w ith fresh engine oil the engine oil filter must be cleaned

See also:

Mash Dirt Track 650 - Owner's Manual > Inspection and adjustment

Mash Dirt Track 650 - Owner's Manual > Inspection and adjustment

This section introduces the technical requirements for proper inspection, maintenance and adjustment of various parts of the G400C motorcycle. Unless stated or indicated in the maintenance period table, you should check and adjust all parts of the G400C motorcycle prior to use.

Mash Dirt Track 650 - Owner's Manual > Valve Clearance & Adjustment

Mash Dirt Track 650 - Owner's Manual > Valve Clearance & Adjustment

The valve clearance should be inspected and adjusted on a cold engine by the following procedures: Remove the caps of the central port and the ignition timing observation port on the left crankcase cover. Remove the caps of the valves on the cylinder head. Turn the nut of the flywheel clockwise until the engraved "T" mark on the flywheel aligns with the engraved line on the top of the crankcase cover, and both intake and exhaust rocker arms do not move but stop at their loosest position. This indicates that the piston is in its top dead center position of the compressing stroke. If the "T" mark is near the proper position but the rocker arms will move when the flywheel rotates within a small angle, the flywheel is not on the compression stroke but exhaust/intake stroke. In this case, continue to turn the flywheel clockwise 360 degrees to reach top dead center position of the compressing stroke, where the valve clearance can be adjusted. Check the valve clearance by inserting a clearance gage into the gap between adjusting screw and the end of the valve.

BMW G310GS

BMW G310GS Honda CBR125RW

Honda CBR125RW Husqvarna 401 Vitpilen

Husqvarna 401 Vitpilen KTM 890 Duke R

KTM 890 Duke R Mash Dirt Track 650

Mash Dirt Track 650 Peugeot Kisbee

Peugeot Kisbee Yamaha Tracer MT-09

Yamaha Tracer MT-09 Honda CBR125RW

Honda CBR125RW Peugeot Kisbee

Peugeot Kisbee Yamaha Tracer MT-09

Yamaha Tracer MT-09