Yamaha Tracer MT09TRA - Service manual > Steering head

Yamaha Tracer MT09TRA - Service manual > Steering head

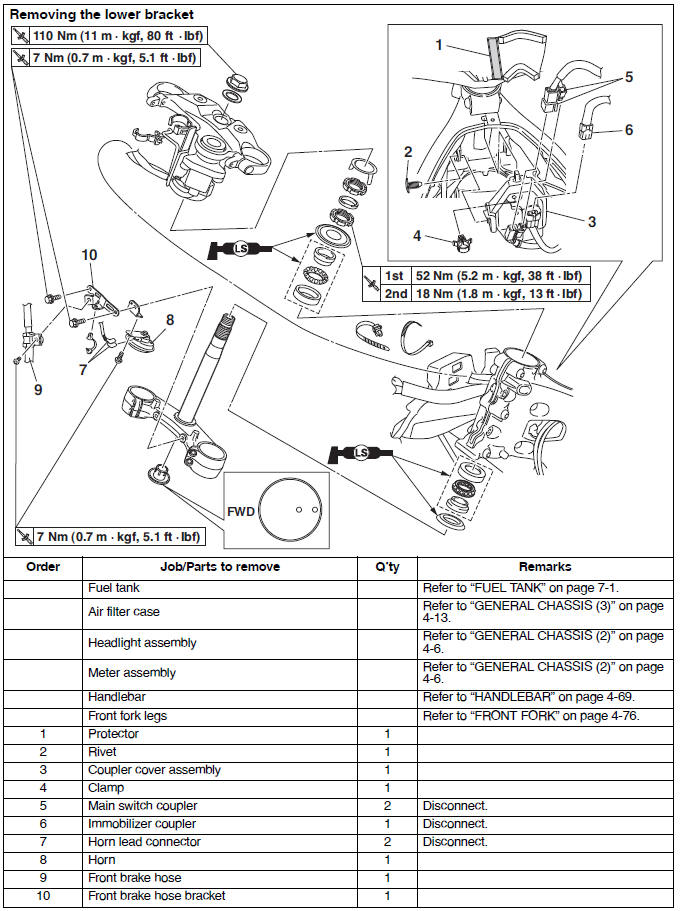

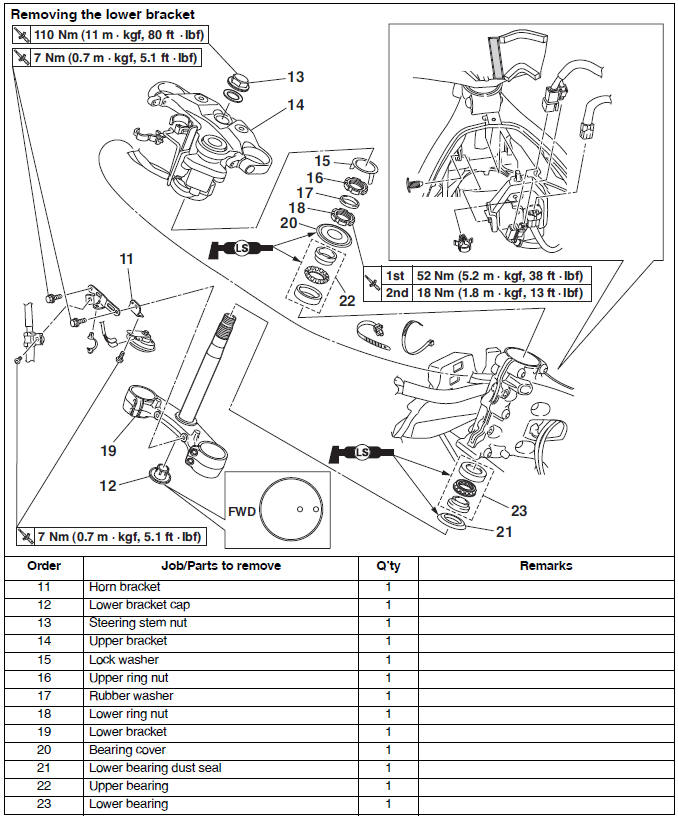

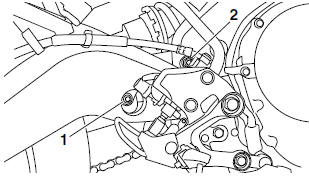

Removing the lower bracket

1. Stand the vehicle on a level surface.

WARNING

Securely support the vehicle so that there is no danger of it falling over

2. Remove:

- Upper ring nut

- Rubber washer

- Lower ring nut "1"

- Lower bracket

WARNING

Securely support the lower bracket so that there is no danger of it falling.

TIP

- Hold the lower ring nut with steering nut wrench, and then remove the upper ring nut with the ring nut wrench.

- Remove the lower ring nut with the steering nut wrench "2".

Ring nut wrench

90890-01268

Ring nut wrench

90890-01268

Spanner wrench YU-01268

Steering nut wrench 90890-01403

Exhaust flange nut wrench YU-A9472

Checking the steering head

1. Wash:

- Bearing

- Bearing race

Recommended cleaning

solvent Kerosene

Recommended cleaning

solvent Kerosene

2. Check:

- Bearing "1"

- Bearing race "2"

Damage/pitting → Replace the bearings and bearing races as a set.

3. Replace:

- Bearing

- Bearing race

a. Remove the bearing races from the steering head pipe "1" with a long rod "2" and hammer.

b. Remove the bearing race "3" from the lower bracket with a floor chisel "4" and hammer.

c. Install a new dust seal and new bearing races.

NOTICE

If the bearing race is not installed properly, the steering head pipe could be damaged.

TIP

- Always replace the bearings and bearing races as a set.

- Whenever the steering head is disassembled, replace the dust seal.

4. Check:

- Upper bracket

- Lower bracket

(along with the steering stem) Bends/cracks/damage → Replace.

Installing the steering head

1. Lubricate:

- Upper bearing

- Lower bearing

Recommended lubricant

Lithium-soap-based grease

Recommended lubricant

Lithium-soap-based grease

2. Install:

- Lower ring nut "1"

- Rubber washer "2"

- Upper ring nut "3"

- Lock washer "4"

Refer to "CHECKING AND ADJUSTING THE STEERING HEAD"

3. Install:

- Upper bracket

- Steering stem nut

TIP

Temporarily tighten the steering stem nut.

4. Install:

- Front fork legs

Refer to "FRONT FORK"

TIP

Temporarily tighten the upper and lower bracket pinch bolts.

5. Tighten:

- Steering stem nut

Steering stem nut 110

Nm (11 m*kgf, 80 ft*lbf)

Steering stem nut 110

Nm (11 m*kgf, 80 ft*lbf)

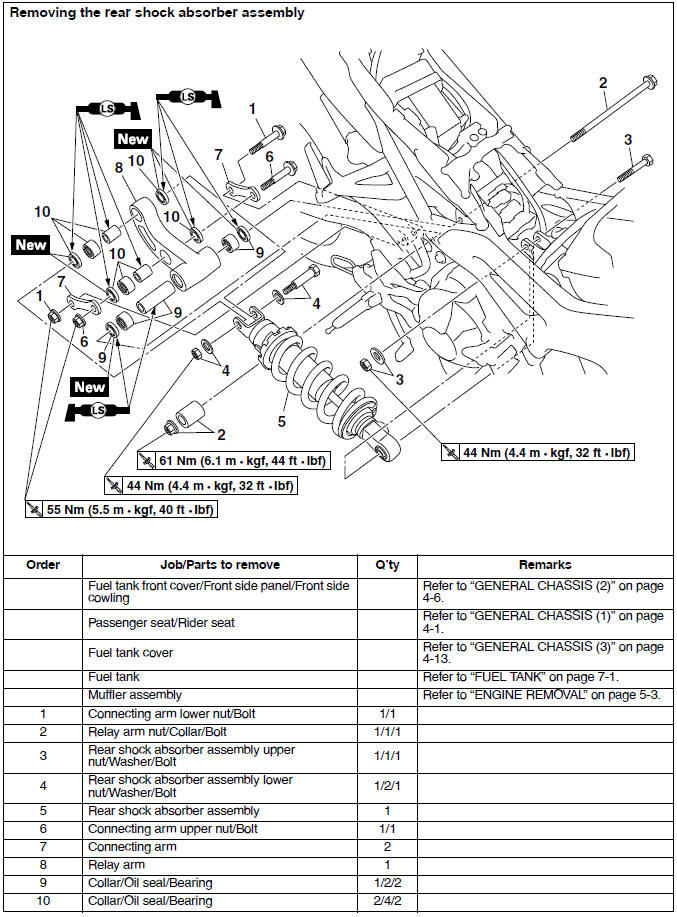

Rear shock absorber assembly

Handling the rear shock absorber

WARNING

This rear shock absorber contains highly compressed nitrogen gas. Before handling the rear shock absorber, read and make sure you understand the following information.

The manufacturer cannot be held responsible for property damage or personal injury that may result from improper handling of the rear shock absorber.

- Do not tamper or attempt to open the rear shock absorber.

- Do not subject the rear shock absorber to an open flame or any other source of high heat. High heat can cause an explosion due to excessive gas pressure.

- Do not deform or damage the rear shock absorber in any way. Rear shock absorber damage will result in poor damping performance.

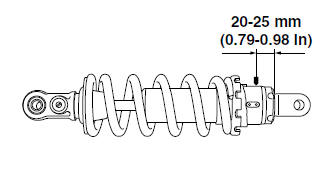

Disposing of a rear shock absorber

1. Gas pressure must be released before disposing of a rear shock absorber. To release the gas pressure, drill a 2-3 mm (0.08-0.12 in) hole through the rear shock absorber at a point 20-25 mm (0.79-0.98 in) from its end as shown.

WARNING

Wear eye protection to prevent eye damage from released gas or metal chips.

Removing the rear shock absorber assembly

1. Stand the vehicle on a level surface.

WARNING

Securely support the vehicle so that there is no danger of it falling over.

TIP

Place the vehicle on the centerstand so that the rear wheel is elevated.

2. Remove:

- Connecting arm lower nut "1"

- Connecting arm lower bolt

- Relay arm nut "2"

- Relay arm bolt

TIP

When removing the bolt, hold the swingarm so that it does not drop down.

3. Remove:

- Rear shock absorber assembly upper nut

- Rear shock absorber assembly upper bolt

- Rear shock absorber assembly

TIP

Remove the rear shock absorber assembly from between the swingarm and frame.

Checking the rear shock absorber assembly

1. Check:

- Rear shock absorber rod.

Bends/damage → Replace the rear shock absorber assembly.

- Rear shock absorber assembly.

Gas leaks/oil leaks → Replace the rear shock absorber assembly.

- Spring

- Bushings.

Damage/wear → Replace the rear shock absorber assembly.

- Bolts.

Bends/damage/wear → Replace.

Checking the connecting arm and relay arm

1. Check:

- Connecting arms "1"

- Relay arm "2"

Damage/wear → Replace.

2. Check:

- Bearings

- Oil seals

Damage/pitting → Replace.

3. Check:

- Collars

Damage/scratches → Replace.

Installing the relay arm

1. Lubricate:

- Collars

- Oil seals

Recommended lubricant

Lithium-soap-based grease

Recommended lubricant

Lithium-soap-based grease

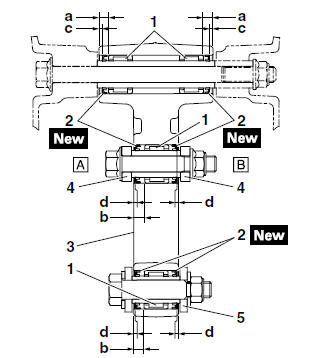

2. Install:

- Bearings "1" (to the relay arm)

- Oil seals "2"

(to the relay arm)

(to the relay arm)

Installed depth "a" 6.0 mm (0.24 in)

Installed depth "a" 6.0 mm (0.24 in)

Installed depth "b" 7.0 mm (0.28 in)

Installed depth "c" 1.5-2.5 mm (0.06-0.10 in)

Installed depth "d" 1.0-2.0 mm (0.04-0.08 in)

TIP

- When installing the oil seals "2" to the relay arm, face the character stamp of the oil seals outside.

- When installing the connecting arms "4" to the relay arm, face the 1RC mark of the connecting arms outside.

3. Relay arm

4. Connecting arm

5. Rear shock absorber assembly

A. Left side

B. Right side

Installing the rear shock absorber assembly

1. Install:

- Rear shock absorber assembly

- Rear shock absorber assembly upper bolt

- Rear shock absorber assembly upper nut

- Relay arm bolt

- Relay arm nut

- Connecting arm lower bolt

- Connecting arm lower nut

TIP

- Install the rear shock absorber assembly upper bolt, relay arm bolt and connecting arm lower bolt from the left.

- When installing the rear shock absorber assembly, lift up the swingarm.

- Install the rear shock absorber assembly with the rebound damping adjusting screw facing the left side of the vehicle.

2. Tighten:

- Rear shock absorber assembly upper nut

- Relay arm nut

- Connecting arm lower nut

Rear shock absorber assembly nut (upper)

Rear shock absorber assembly nut (upper)

44 Nm (4.4 m*kgf, 32 ft*lbf)

Relay arm nut 61 Nm (6.1 m*kgf, 44 ft*lbf)

Connecting arm lower nut 55 Nm (5.5 m*kgf, 40 ft*lbf)

See also:

Yamaha Tracer MT09TRA - Service manual > Swingarm

Yamaha Tracer MT09TRA - Service manual > Swingarm

Removing the swingarm 1. Stand the vehicle on a level surface. WARNING

BMW G310GS

BMW G310GS Honda CBR125RW

Honda CBR125RW Husqvarna 401 Vitpilen

Husqvarna 401 Vitpilen KTM 890 Duke R

KTM 890 Duke R Mash Dirt Track 650

Mash Dirt Track 650 Peugeot Kisbee

Peugeot Kisbee Yamaha Tracer MT-09

Yamaha Tracer MT-09 Honda CBR125RW

Honda CBR125RW Peugeot Kisbee

Peugeot Kisbee Yamaha Tracer MT-09

Yamaha Tracer MT-09