Mash Dirt Track 650 - Owner's Manual > Throttle

Mash Dirt Track 650 - Owner's Manual > Throttle

Inspect the throttle cable for deformed, twisted or damaged locations along the cable length.

Measure the throttle free-play. Tum the throttle against one side of the free stroke, and draw a straight line between the bar and the balance weight. Then turn the bar to lean it against the other side of the free stroke; measure the distance of the straight line, i.e. the throttle bar free stroke.

Free play: 2 6mm

If the throttle free-play is insufficient or too large, make adjustments as necessary.

Fine adjustment:

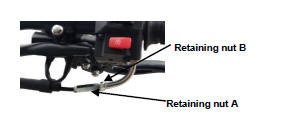

Move the rubber lagging to expose the adjuster. Unscrew the retaining Nut A, and turn the adjuster until free-play is within specification. Tighten the retaining Nut A and re-install the protective rubber lagging.

Adjusting methods:

Coarse adjustment: If the fine adjustment is not sufficient, remove the throttle cable from the throttle body and unscrew the retaining Nut B to increase the free-play. Tighten the retaining Nut B after the adjustment.

After all adjustments, verify the throttle can turn smoothly from full open to full close at any handlebar position. If there is any impediment to turning the throttle smoothly, adjust or replace the throttle or cable.

Warning

Too much or too little throttle free-play or operating the motorcycle with throttle impediments is very dangerous and can result in sudden acceleration and/or loss of control of the vehicle.

Brake System

The front brake and the rear brake is hydraulic disk type, Inspect the brake system prior to each ride. Properly functioning brake systems are vitally important to your personal safety. Check for fluid leaks, fluid level, brake shoe wear, and rotor and drum condition. Also check lever free play frequently.

Front Brake

Pull the brake lever lightly until you feel tension, then check the lever free-play. If the brake lever has no free-play or is too loose, there is a potential brake system fault. Inspect brake system thoroughly.

Brake lever free play 10 20mm

Rear Brake

Push the brake pedal downward by hand, check the brake pedal free-play. The rear brake pedal free-play should be at least 18mm but no more than 25 mm.

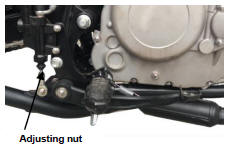

If the free-play is outside this range, the pedal can be adjusted by adjusting the rear brake adjustment nut near the rear wheel. To make adjustment, turn the rear brake adjusting nut clockwise to reduce and counter clockwise to increase the free operating stroke of the brake pedal.

Twirl the adjustment nut to change the pedal stroke. Validate that the pedal free stroke meets specification.

Caution

Brake pedal free-play is important. If the brake pedal free- play is too little or zero, the brakes may drag leading to brake failure. If the free-play is too large, the brakes may not actuate when the lever is pressed. These are dangerous conditions that can lead to loss of control of the vehicle. Do not ride the vehicle if the brake free-play is out of range.

Brake Fluid Level

Be sure the motorcycle is on flat ground, Push the brake pedal downward by hand or turn the bar and check the brake fluid when the brake master cylinder cover is in a level position.

Check the brake fluid level through the master cylinder view port. The fluid level will drop over time as the brake pads wear. If the brake fluid level is too low (LOWER) 1, thoroughly inspect the brake system for leaks. If there are no leaks, add fluid as necessary. If leaks are found, do not operate the vehicle until the brake system has been repaired.

Caution

Brake fluid is flammable. Avoid contact with skin and eyes. If you come in contact with brake fluid, immediately run under water and contact a doctor. If brake fluid comes in contact with your eyes, immediately seek medical attention.

Caution

- Brake fluid cannot exceed the upper limit.

- When adding brake fluid, use special care. Do not allow dust, water or other foreign material to contaminate the master cylinder. If brake fluid is low, this may be a sign of failure in the brake system. Do not ride the vehicle until the brake system has been inspected and repaired by a qualified technician.

Adding Brake Fluid

Turn the handle bar so that the brake master cylinder is horizontal with the ground.

Remove dust and foreign material from the exterior of the brake master cylinder. Loosen the brake master cylinder cover, then remove the rubber diaphragm.

Add DOT3 brake fluid into the master cylinder, then re-insert the diaphragm and cover. Tighten the cover. Make sure that no foreign materials enter into the brake system.

If the brake system is not firm, there may be brake contamination or the brakes might need to be bled of air. Contact your Genuine Motorcycles dealer for service.

Caution

Brake fluid cannot exceed the upper limit.

When adding brake fluid, use special care. Do not allow dust, water or other foreign material to contaminate the master cylinder. If brake fluid is low, this may be a sign of failure in the brake system. Do not ride the vehicle until the brake system has been inspected and repaired by a qualified technician.

Caution

Do not mix brake fluid with other liquids; If brake fluid spills onto plastic or painted surfaces, wipe off immediately. In the event brake fluid splashes into the eyes or on the skin, immediately flush with large amounts of fresh water and immediately see a doctor.

See also:

Mash Dirt Track 650 - Owner's Manual > Valve Clearance & Adjustment

Mash Dirt Track 650 - Owner's Manual > Valve Clearance & Adjustment

The valve clearance should be inspected and adjusted on a cold engine by the following procedures: Remove the caps of the central port and the ignition timing observation port on the left crankcase cover. Remove the caps of the valves on the cylinder head. Turn the nut of the flywheel clockwise until the engraved "T" mark on the flywheel aligns with the engraved line on the top of the crankcase cover, and both intake and exhaust rocker arms do not move but stop at their loosest position. This indicates that the piston is in its top dead center position of the compressing stroke. If the "T" mark is near the proper position but the rocker arms will move when the flywheel rotates within a small angle, the flywheel is not on the compression stroke but exhaust/intake stroke. In this case, continue to turn the flywheel clockwise 360 degrees to reach top dead center position of the compressing stroke, where the valve clearance can be adjusted. Check the valve clearance by inserting a clearance gage into the gap between adjusting screw and the end of the valve.

Mash Dirt Track 650 - Owner's Manual > Brake Pads

Mash Dirt Track 650 - Owner's Manual > Brake Pads

If the brake pad wear indicator gaps touch the side of the brake disc, the brake pads need replacement.

BMW G310GS

BMW G310GS Honda CBR125RW

Honda CBR125RW Husqvarna 401 Vitpilen

Husqvarna 401 Vitpilen KTM 890 Duke R

KTM 890 Duke R Mash Dirt Track 650

Mash Dirt Track 650 Peugeot Kisbee

Peugeot Kisbee Yamaha Tracer MT-09

Yamaha Tracer MT-09 Honda CBR125RW

Honda CBR125RW Peugeot Kisbee

Peugeot Kisbee Yamaha Tracer MT-09

Yamaha Tracer MT-09