Honda CBR125RW - Service manual > Brake Fluid

Honda CBR125RW - Service manual > Brake Fluid

Spilled fluid can damage painted, plastic or rubber parts. Place a rag over these parts whenever the system is serviced.

- Do not mix different types of fluid, as they are not compatible with each other.

- Do not allow foreign material to enter the system when filling the reservoir.

- When the fluid level is low, check the brake pads for wear.

- A low fluid level may be due to wear of the brake pads. If the brake pads are worn and caliper pistons are pushed out, this accounts for a low fluid level. If the brake pads are not worn and fluid level is low, check the entire system for leaks.

FRONT BRAKE

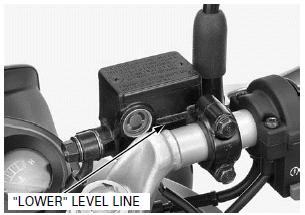

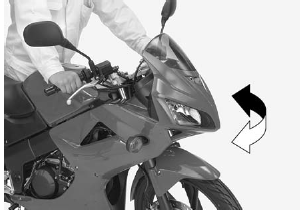

Turn the handlebar so that the reservoir is level and check the front brake fluid level through the sight glass.

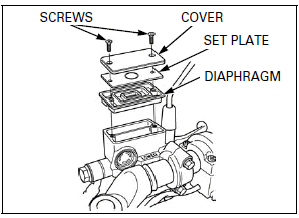

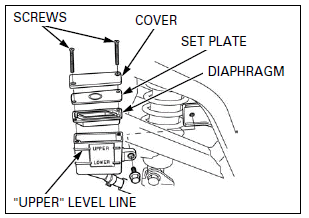

Remove the cover screws, reservoir cover, set plate and diaphragm.

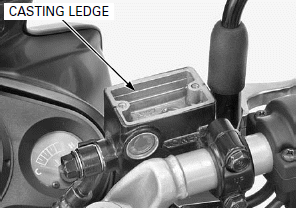

Add the reservoir with DOT 3 or DOT 4 brake fluid from a sealed container to the casting ledge.

Install the diaphragm, set plate and reservoir cover.

Install and tighten the cover screws to the specified torque.

TORQUE: 1.5 N-m (0.2 kgf-m, 1.1 lbf-ft)

REAR BRAKE

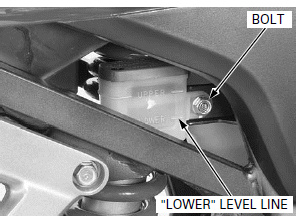

Support the motorcycle on a level surface, and check the rear brake fluid level.

If you will add the brake fluid, remove the bolt.

Remove the cover screws, reservoir cover, set plate and diaphragm.

Add the reservoir with DOT 3 or DOT 4 brake fluid from a sealed container to the "UPPER" level line.

Install the diaphragm, set plate and reservoir cover.

Install and tighten the cover screws to the specified torque.

TORQUE: 1.5 N-m (0.2 kgf-m, 1.1 lbf-ft)

Install the bolt.

BRAKE PADS WEAR

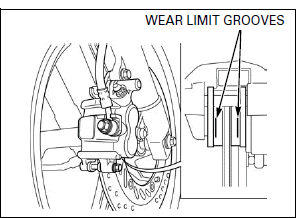

FRONT BRAKE PADS

Check the brake pads for wear.

Always replace the brake pads as a set to assure even disc pressure.

Replace the brake pads if either pad is worn to the bottom of wear limit grooves.

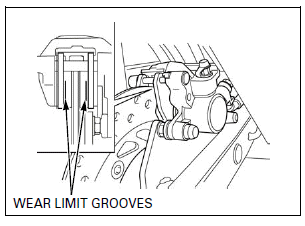

REAR BRAKE PADS

Check the brake pads for wear.

Always replace the brake pads as a set to assure even disc pressure.

Replace the brake pads if either pad is worn to the bottom of wear limit grooves.

BRAKE SYSTEM

INSPECTION

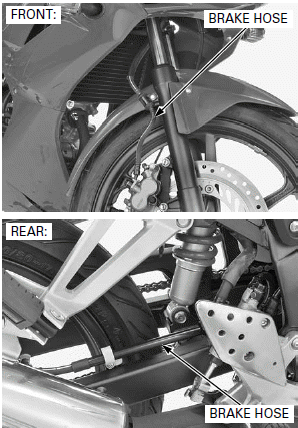

Firmly apply the brake lever or pedal, and check that no air has entered the system.

If the lever or pedal feels soft or spongy when operated, bleed the air from the system.

Inspect the brake hose and fittings for deterioration, cracks and signs of leakage.

Tighten any loose fittings.

Replace hoses and fittings as required.

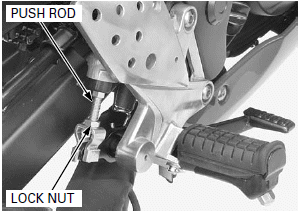

BRAKE PEDAL HEIGHT ADJUSTMENT

Loosen the lock nut and turn the push rod until the correct pedal height is obtained.

After adjustment, tighten the lock nut securely.

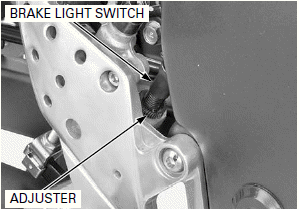

BRAKE LIGHT SWITCH

The front brake light switch does not require adjustment.

Adjust the brake light switch so that the brake light comes on just prior to the brake actually being engaged.

If the light fails to come on, adjust the switch so that the light comes on at the proper time.

NOTE:

Hold the switch body and turn the adjuster. Do not turn the switch body.

CLUTCH SYSTEM

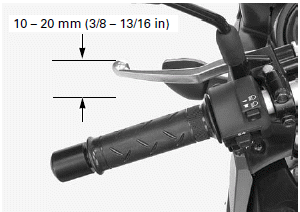

Measure the clutch lever freeplay at the end of the clutch lever.

FREEPLAY: 10 - 20 mm (3/8 - 13/16 in)

The adjuster may be damaged if it is positioned too far out, leaving minimal thread engagement.

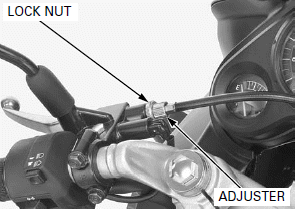

Minor adjustment is made with the upper adjuster at the clutch lever.

Loosen the lock nut and turn the adjuster.

If the adjuster is threaded out near its limit and the correct freeplay cannot be obtained, turn the adjuster all the way in and back out one turn.

Tighten the lock nut while holding the adjuster.

Recheck the clutch lever freeplay.

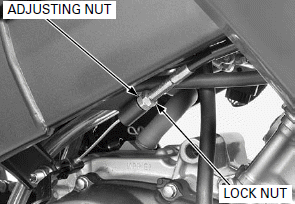

Major adjustment is made with the lower adjusting nut at the clutch lifter lever.

Loosen the lock nut and turn the adjusting nut to adjust the freeplay.

Tighten the lock nut while holding the adjusting nut.

If proper freeplay cannot be obtained, or the clutch slips during test ride, disassemble and inspect the clutch.

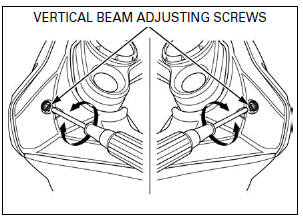

HEADLIGHT AIM

Support the motorcycle in an upright position.

Adjust the headlight aim vertically by turning the vertical beam adjusting screw.

A clockwise rotation moves the beam up and counterclockwise rotation moves the beam down.

Adjust the headlight aim as specified by local laws and regulations

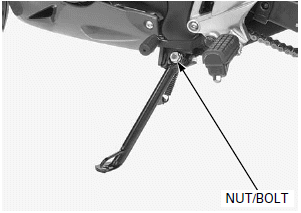

SIDESTAND

Support the motorcycle using a safety stand or hoist.

Check the sidestand spring for damage or loss of tension.

Check the sidestand assembly for freedom of movement and lubricate the sidestand pivot if necessary.

TORQUE:

Sidestand pivot bolt: 18 N-m (1.8 kgf-m, 13 lbf-ft)

Sidestand pivot nut: 44 N-m (4.5 kgf-m, 32 lbf-ft)

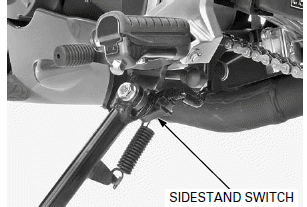

Check the sidestand ignition cut-off system:

- Sit astride the motorcycle and raise the sidestand.

- Start the engine with the transmission into neutral, then shift the transmission into gear, with the clutch lever squeezed.

- Move the sidestand full down.

- The engine should stop as the sidestand is lowered.

If there is a problem with the system, check the sidestand switch.

SUSPENSION

FRONT SUSPENSION INSPECTION

Check the action of the forks by operating the front brake and compressing the front suspension several times.

Check the entire assembly for signs of leaks, damage or loose fasteners.

Loose, worn or damaged suspension parts impair motorcycle stability and control.

Replace damaged components which cannot be repaired.

Tighten all nuts and bolts.

REAR SUSPENSION INSPECTION

Check the action of the rear shock absorber by compressing the rear end several times.

Check the entire shock absorber assembly for leaks, damage or loose fasteners.

Loose, worn or damaged suspension parts impair motorcycle stability and control.

Replace damaged components which cannot be repaired.

Tighten all nuts and bolts.

Support the motorcycle using a safety stand or hoist, raise the rear wheel off the ground.

Check for worn swingarm bushings by grabbing the rear wheel and attempting to move the wheel side to side.

Replace the bushings if any looseness to noted.

NUTS, BOLTS, FASTENERS

Check that all chassis nuts, screws and bolts are tightened to their correct torque values.

Check that all cotter pins, safety clips, hose clamps and cable stays are in place and properly secured.

WHEELS/TIRES

Support the motorcycle using a safety stand or hoist, raise the front wheel off the ground.

Hold the front fork leg and move the front wheel sideways with force to see if the wheel bearings are worn.

Support the motorcycle using a safety stand or hoist, raise the rear wheel off the ground.

Hold the swingarm and move the rear wheel sideways with force to see if the wheel and driven flange bearings are worn.

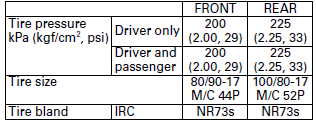

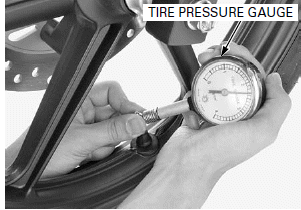

Check the tire pressure with a tire pressure gauge when the tires are cold.

RECOMMENDED TIRE PRESSURE AND TIRE SIZE:

Check the tires for cuts, embedded nails, or other damage.

Check the front and rear wheels for trueness.

Measure the tread depth at the center of the tires.

Replace the tires when the tread depth reaches the following limits.

MINIMUM TIRE TREAD DEPTH

FRONT: 0.8 mm (0.03 in)

REAR: 0.8 mm (0.03 in)

STEERING HEAD BEARINGS

Support the motorcycle using a safety stand or hoist, raise the front wheel off the ground.

Check that the handlebar moves freely from side to side. Make sure the control cables do not interfere with the handlebar rotation.

Check for steering stem bearings by grabbing the fork legs and attempting to move the front fork forward to backward.

If the handlebar moves unevenly, binds, or has vertical movement, inspect the steering head bearings.

See also:

Honda CBR125RW - Service manual > Drive Chain

Honda CBR125RW - Service manual > Drive Chain

DRIVE CHAIN SLACK INSPECTION Never inspect and adjust the drive chain while the engine is running. Turn the ignition switch OFF, support the motorcycle on its sidestand and shift the transmission into neutral.

BMW G310GS

BMW G310GS Honda CBR125RW

Honda CBR125RW Husqvarna 401 Vitpilen

Husqvarna 401 Vitpilen KTM 890 Duke R

KTM 890 Duke R Mash Dirt Track 650

Mash Dirt Track 650 Peugeot Kisbee

Peugeot Kisbee Yamaha Tracer MT-09

Yamaha Tracer MT-09 Honda CBR125RW

Honda CBR125RW Peugeot Kisbee

Peugeot Kisbee Yamaha Tracer MT-09

Yamaha Tracer MT-09