Honda CBR125RW - Service manual > Fuel System (PGM-FI)

Honda CBR125RW - Service manual > Fuel System (PGM-FI)

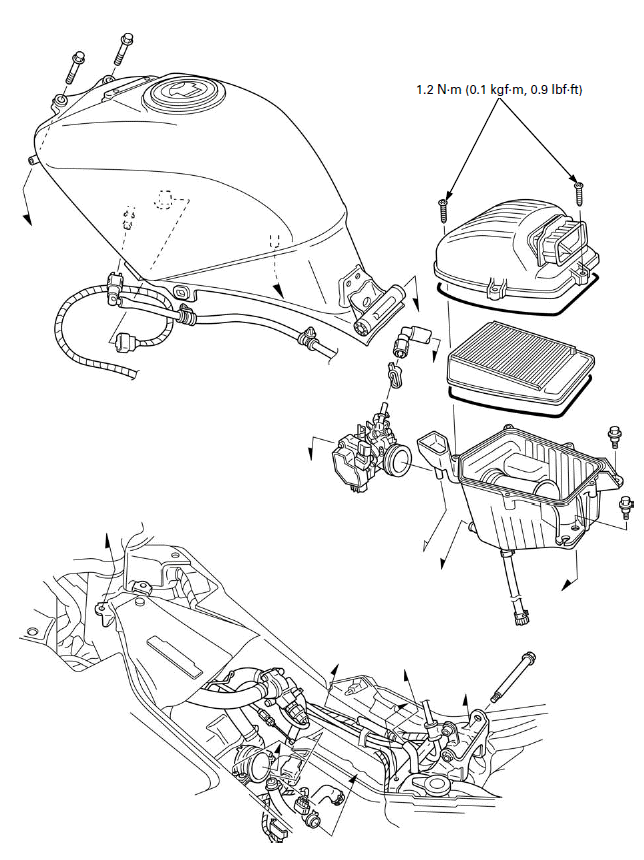

COMPONENT LOCATION

SERVICE INFORMATION

GENERAL

- Work in a well ventilated area. Smoking or allowing flames or sparks in the work area or where gasoline is stored can cause a fire or explosion.

- Before disconnecting the fuel feed hose, relieve fuel pressure from the system by disconnecting the quick connect fitting at the fuel pump.

- Bending or twisting the control cables will impair smooth operation and could cause the cables to stick or bind, resulting in loss of vehicle control.

- Do not apply commercially available carburetor cleaners to the inside of the throttle bore.

- Do not snap the throttle valve from full open to full close after the throttle cable has been removed. It may cause incorrect idle operation.

- Seal the intake ports with tape or a clean cloth to keep dirt and debris from entering the engine after the throttle body has been removed.

- Do not damage the throttle body. It may cause incorrect throttle valve operation.

- Prevent dirt and debris from entering the throttle bore and air passages after the throttle body has been removed. Clean them using a compressed air if necessary.

- The throttle body is factory pre-set. Do not disassemble in a way other than shown in this manual.

- Do not loosen or tighten the white painted nut and screw of the throttle body. Loosening or tightening them can cause throttle valve and idle control failure.

- The parts of the throttle body not shown in this manual should not be disassembled.

- Always replace the packing when the fuel pump is removed.

- A faulty PGM-FI system is often related to poorly connected or corroded connectors. Check those connections before proceeding.

- The PGM-FI system is equipped with the Self-Diagnostic System described. If the MIL blinks, follow the Self-Diagnostic Procedures to remedy the problem.

- When checking the PGM-FI system, always follow the steps in the troubleshooting table.

- The PGM-FI system is provided with fail-safe function to secure a

minimum running capability even when there is any trouble in the system.

When any abnormality is detected by the self-diagnosis function, running

capability is secured by making use of the numerical values of a situation

preset in advance in the simulated program map.

It must be remembered, however, that when any abnormality is detected in injector, the fail-safe function stops the engine to protect it from damage.

- When disassembling the PGM-FI system parts, note the location of the O-rings. Replace them with new ones upon reassembly.

- Use a digital tester for PGM-FI system inspection.

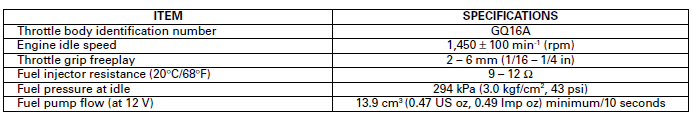

SPECIFICATIONS

TORQUE VALUES

Bank angle sensor mounting screw 1.2 N-m (0.1 kgf-m, 0.9 lbf-ft)

ECT sensor 24.5 N-m (2.5 kgf-m, 18 lbf-ft)

Fuel pump setting plate nut - For tightening sequence

Injector joint mounting bolt 5.1 N-m (0.5 kgf-m, 3.8 lbf-ft)

O2 sensor 25 N-m (2.5 kgf-m, 18 lbf-ft)

Sensor unit torx screw 3.4 N-m (0.3 kgf-m, 2.5 lbf-ft)

IACV setting plate torx screw 2.1 N-m (0.2 kgf-m, 1.5 lbf-ft)

Throttle cable stay screw 3.4 N-m (0.3 kgf-m, 2.5 lbf-ft)

Insulator band screw -

Air cleaner cover screw 1.2 N-m (0.1 kgf-m, 0.9 lbf-ft)

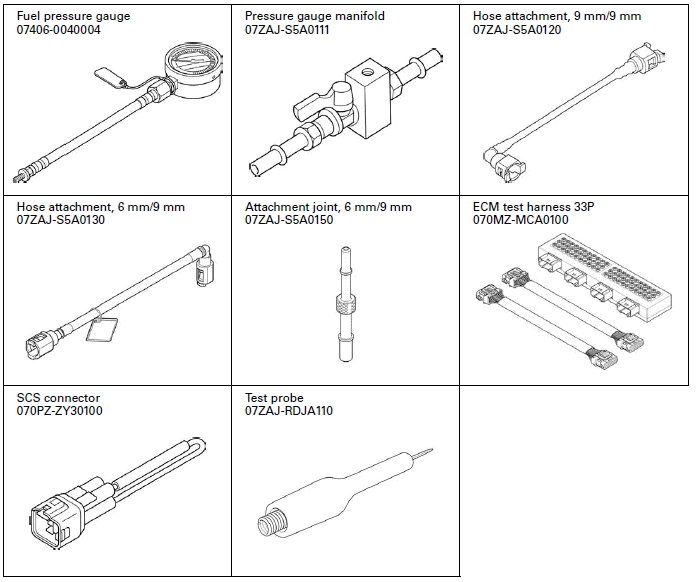

TOOLS

See also:

Honda CBR125RW - Service manual > Lubrication System

Honda CBR125RW - Service manual > Lubrication System

LUBRICATION SYSTEM DIAGRAM CAMSHAFT ROCKER ARM CRANKSHAFT COUNTERSHAFT MAINSHAFT OIL STRAINER SCREEN OIL PUMP

Honda CBR125RW - Service manual > PGM-FI

Honda CBR125RW - Service manual > PGM-FI

PGM-FI SYMPTOM TROUBLESHOOTING When the motorcycle has one of these symptoms, check the DTC or MIL blinking, refer to the DTC index and begin the appropriate troubleshooting procedure. If there are no DTC/MIL blinking stored in the ECM memory, do the diagnostic procedure for the symptom, in sequence listed below, until you find cause.

BMW G310GS

BMW G310GS Honda CBR125RW

Honda CBR125RW Husqvarna 401 Vitpilen

Husqvarna 401 Vitpilen KTM 890 Duke R

KTM 890 Duke R Mash Dirt Track 650

Mash Dirt Track 650 Peugeot Kisbee

Peugeot Kisbee Yamaha Tracer MT-09

Yamaha Tracer MT-09 Honda CBR125RW

Honda CBR125RW Peugeot Kisbee

Peugeot Kisbee Yamaha Tracer MT-09

Yamaha Tracer MT-09